1. Applications:

The TBQS Quantometer is a turbine meter for operational natural gas-volume measurement and for other non-aggressive gases such as propane, butane, air, carbon dioxide,or inert gases used in internal and controlling processes of various types, especially in industrial thermoprocessing facilities.

2. Features:

Meter size: G10 to G1600

Nominal sizes: From DN25 (1") to DN200(8")

Measuring range: 1:10 or 1:20

Flow rates: From 2 to 2500 m³/h

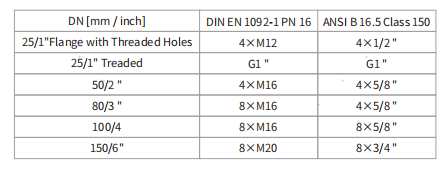

Pressure class: PN16 and ANSI 150

Maintenance free based on permanent lubrication of the ball bearings

Standard engineered polymer material index head optional aluminum index head Rotating index head (355°)

Horizontal and vertical mounting position

Anodized high strength aluminum meter body

Optional manual lubrication of the ball bearings by means of oil pump

Recommended straight inlet pipe ≥3DN and outlet pipe ≥2DN

Approval according to PED (PED2014/68/EU)

3. Operating Principle:

The Quantometer is a turbine gas meter that registers the operating volume using an eight-digit mechanical counter. Via pulses the operating volume can be transferred to an electronic volume corrector and converted to nommal or standard conditions.

The TBQS Ouantometer is a volume flow meter. The flow of the gas to be measured causes the turbine rotor to rotate. The gas flows narrowed on an annular cross section, is accelerated and directed onto the smooth-running Aluminum rotor. The number o rotations is proportional to the measured gas volume; the frequency of rotations is proportional to the actual gas flow. The rotation of the rotor is connected to a speed-reducing gear train and transmitted via a magnetic coupling from the gas pressurized area to the adjustable 8-digit roller counter in the atmospheric environment.

The actual volume flow can be transmited to electronic volume correctors or data loggers via low frequency (LF-) pulses generated by Reed contacts. In the meter's index head is also located an anti-tampering contact.

The rotation of the rotor can be scanned additionally with one freguency (HF-) sensor as an option. The HF-sensor signal allows the determination of the actual gas flow in high-resolution.

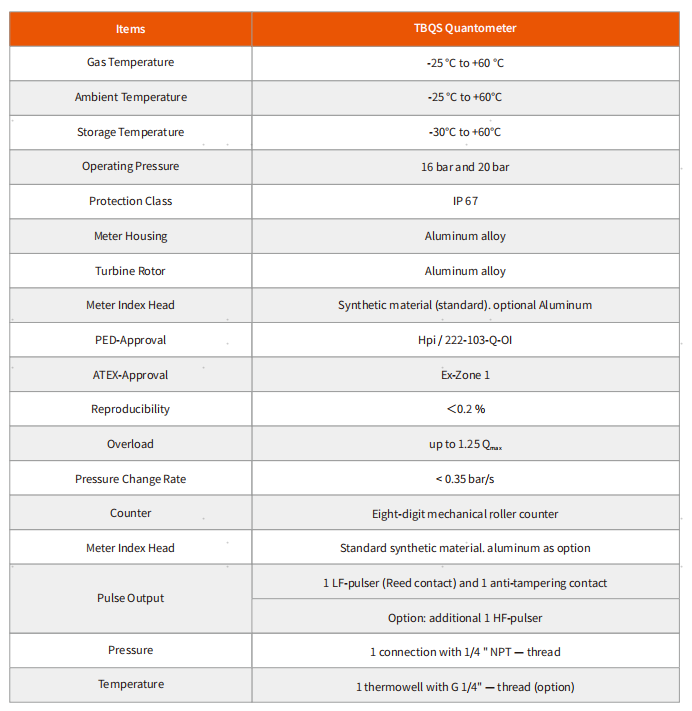

4. Technical Parameters:

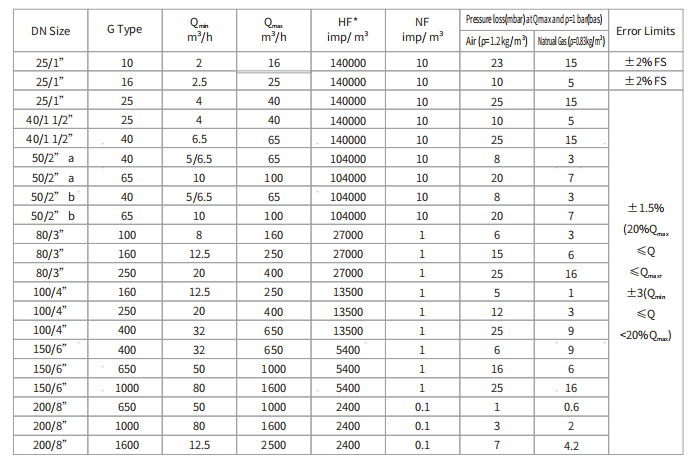

5. Error Limits:

The TBQS Quantometers are all initially calilbrated within the specified measurement errors. Reduced measurement errors limits are optionally available.

The TBQS Quantometers are manufactured with large measurement ranges due to the precision machining of the parts and a reproducible assembly process.

The standard calibrated measurement range for the TBQS is 1:10 or 1:20 under atmospheric conditions.

6. Sizing Table:

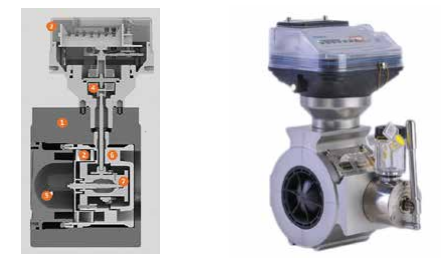

7. Meter Design:

1) Pressure containing housing

2) Turbine wheel

3) Mechanical counter/index

4) Magnetic coupling

5) Inlet flow straightener

6) Measuring cartridge

7) Gear train

8. Connections:

TBQS Quantometer housings are manufactured without flanges as a "sandwich" design to be installed between the two inlet and outlet pipe flanges on a standard basis with raised face (RF) flanges according to DIN/EN 1092-1 Or ANSI B 16.5 for class 150 with a maximum operating pressure of 20 bar/ 2,0 MPa. The TBQS DN 25 M" is designed as flange version with threaded

holes or as a threaded pipe version with a thread of G1".